ISTECH - Cleaning by (Ultra) High-Pressure Water Jetting

ISTECH Metal Finish BV strives to provide high quality services and it is our goal to get your equipment and or piping system up and running to normal / standard operating conditions with minimal down time.

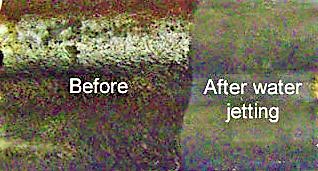

High-pressure water jetting also referred to as hydrojetting or high-pressure pipe cleaning is a powerful cleaning method designed to carry out tube cleaning, pipe cleaning, surface cleaning, boiler cleaning, tank cleaning.

This process blasts pressurized water on the fouled surfases or through the affected pipe, removing all solids and residues for a thorough, long-lasting clean.

Fig.1: Pipe cleaning nozzle for internal pipe & tube cleaning

Cleaning by High Pressure Water Jetting or Ultra High Pressure Water Jetting is a perfect way to carry out maintenance and cleaning of:

- Heat exchangers

- Exhaust Gas Boiler / Econimizers (US) / Economisers (UK)

- Auxiliary Boilers: Boiler (burner) furnaces, burner gas sides, water or smoke tubes

- Combi Boilers

- Tank cleaning: (fuel) oil tanks, cargo tanks both Mild Steel and Stainless Steel

- Cooling water/ steam tubes or piping systems

- (Gas) Scrubbers

CLeaning by (ULTRA) High Pressure Water Jetting to be used for cleaning of:

- Descaling to remove water scale

- Mild degreasing such as sludge, mild scale, oily dirty water or after repair job.

- Soot cleaning / Carbon Black cleaning of smoke tubes, burner gas side (furnace) or exhaust gas side

(ULTRA) High Pressure Water Jetting can be carried out on site or on board of vessels for cleaning of:

- Hot Water / Steam Boilers

- Exhaust Gas Boilers / Economizers (US) / Economisers (UK)

- Thermal Oil Boilers and Thermal Oil Piping Systems

- Steam Generators / Heat Exchangers

- Coated Steel and Stainless Steel Water Tanks

- Coated Steel and Stainless Steel Process Tanks

- Stainless Steel Brewery Tanks

- Mild Steel and Stainless Steel Equipment

- Mild Steel and Stainless Steel Installations

- Coated Steel and Stainless Steel Cargo Tanks

- Stainless Steel Heating Coils

- Mild Steel and Stainless Steel Cargo Piping Systems

- Mild Steel and Stainless Steel Vent Piping

High pressure tube & pipe cleaning is the process for cleaning and maintaining fouled tubes. Sometimes chemical cleaning is required to remove deposits and obstructions, which are caused by the liquids, which run through the tubing. The chemical tube cleaning process can help prevent corrosion due to deposits, which can also create tube failure.

Fig.2: External pipe cleaning by high pressure water jetting

ISTECH Metal Finish BV has over 35 years of worldwide experience with all kinds of CLEANING projects for the:

- Maritime Shipping Industry

- Offshore Industry

- Petrochemical Industry

- Manufacturing Industry

- Food & Beverage Industry

- Fishing Industry

- Government

Cleaning by (Ultra) High Pressure Water Jetting is carried out to achieve an effective cleaning to get equipment back in optimal process condtion. Pollution of any kind on water tubes or smoke pipes inside heat exchangers and boilers are interfering good heat transfer with damages to the pipes (leakages / cracks) or can lead to a total shut down/ break down of the heat exchanger / boiler.

ISTECH - 24/7 Troubleshooting and Services Worldwide

ISTECH Metal Finish BV - cleaning procedures for (ULtra) high pressure water jetting

Our cleaning procedures are assured to match any fouling with the right equipment and the required expertise needed for the job. The cleaning can be carried out succesfully by using a specific type of High Pressure Cleaner to achieve an effective cleaning to get equipment back in optimal process condtion. Pollution of any kind on water tubes or smoke pipes inside heat exchangers and boilers are interfering good heat transfer with damages to the pipes (leakages / cracks) or can lead to a total shut down/ break down of the heat exchanger / boiler.

ISTECH is specialized in MECHANICAL Surface Treatment and Chemical technical cleaning Of Stainless steel and mild steel and surface repair of Stainless Steel by:

- Pickling and Passivation

- Chemical Passivation

- Corrosion Treatment (Chemical)

- Corrosion Treatment (Mechanical)

- Grinding and Polishing

- FOSFA Cleaning

- Cleaning and Degreasing

- Marine Scrubber Repair Service

- Cargo Pump Repair Service

- Chemical Technical Cleaning

- (Ultra) High Pressure Water Jetting

If any questions or requests please do not hesitate to contact us.

STAINLESS STEEL SURFACE BUFFING - GRINDING - POLISHING - WELDING

CLEANING OPERATIONS - PICKLING AND PASSIVATION