Inspection

Worldwide Stainless Steel Condition Inspection and Stainless Steel Corrosion Damage Inspection

A clean and passive surface finish is crucial to corrosion resistance. Stainless steel is protected from corrosion by its passive layer - a thin, impervious, invisible, surface layer that is primarily chromium oxide. Technical inspections and report subjects:

- Stainless Steel Surface Condition

- Corrosion Analysis

- Pitting Corrosion Depth Measurements

- Surface Roughness Testing

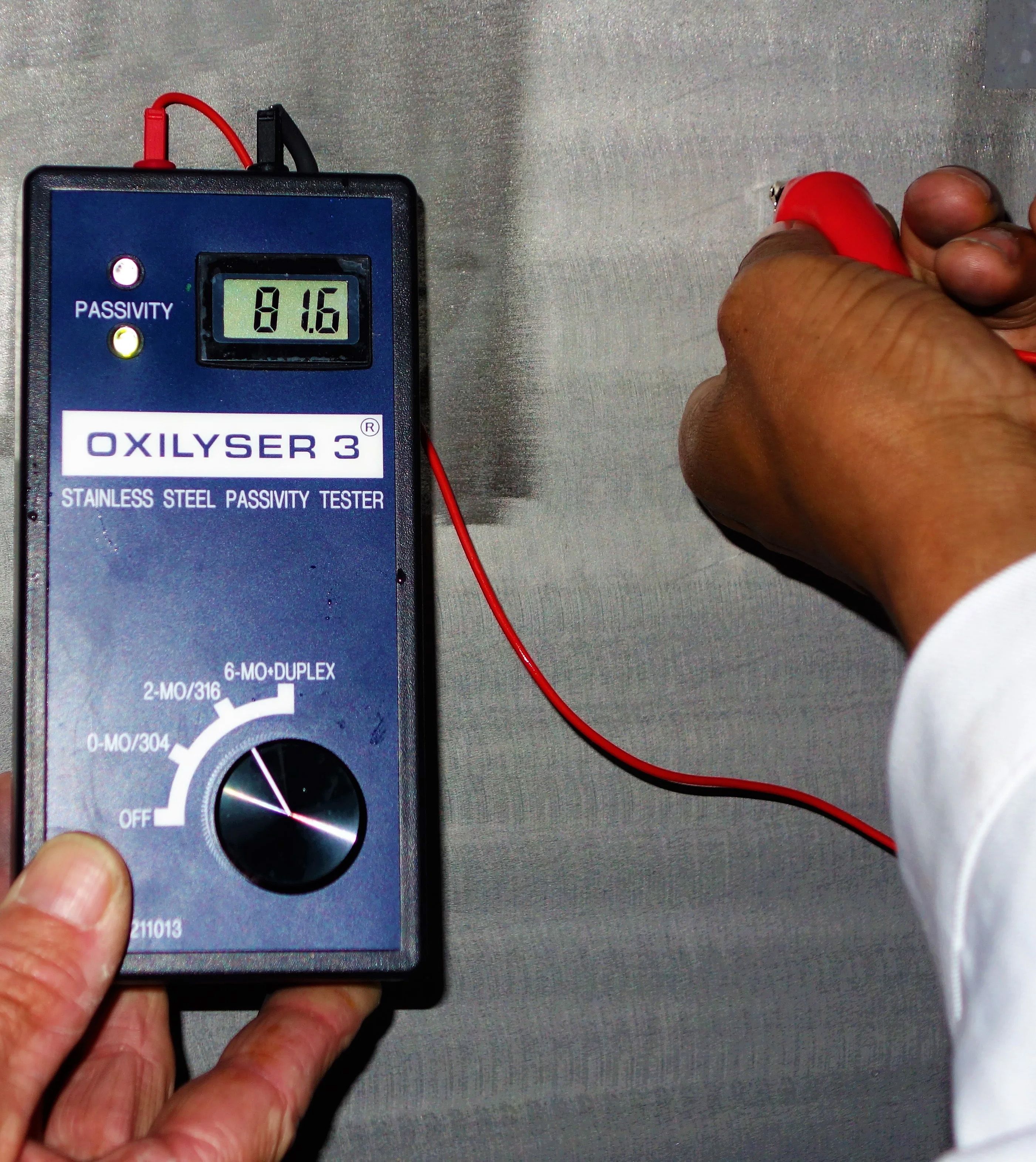

- Passivity Testing

- Weld Inspection (NDT)

- Endoscope Camera Test (interior piping condition)

- Inspection Report afterwards

The oxygen content of the atmosphere or of aerated aqueous solutions is normally sufficient to create and maintain ('self-heal') this passive layer. Unfortunately, surface defects and imperfections introduced during manufacturing or caused by aggressive chemical loadings may drastically disturb this 'self-healing' process and reduce resistance to several types of local corrosion. Thus, as regards hygiene and corrosion, a final cleaning process is required to restore an acceptable surface quality.

Stainless Steel Surface Treatment needs to be carried out to remove or clean:

- Corrosion / Rust

- Ferrous Contamination / Free Irons

- Light Discoloration

- Hydrocarbons

- Starting Pitting

- Cargo Residue

Chemical cleaning with Nitric Acid in compliance with:

- FOSFA Qualifications & Requirements

Passivation is a chemical treatment with a specific acid formulation that removes free-iron or other surface contamination from the stainless steel while simultaneously promoting the formation of a passive chromium/nickel oxide layer to act as a barrier to further corrosion.

Stainless Steel Surface Treatment needs to be carried out to restore or to repair:

- Damaged passivation layers brinning back to a thick uniform chromium oxide layer

- Unstable passivity readings bringing back a stable passive chromium oxide layer

- Stainless Steel Corrosion resistance interference by ferrous contamination / free irons

ISTECH worldwide experience and specialized

ISTECH has more than 35 years experience worldwide in Stainless Steel Surface Treatment and inspections of:

- Stainless Steel Cargo Tanks, Heating Coils and Cargo Lines

- Stainless Steel Piping

- Stainless Steel Scrubbers

- Stainless Steel Brewery Equipment and Installations

- Stainless Steel Fish Processing Lines and Equipment

- Stainless Steel Public (Art) Objects

ISTECH is specialized in Chemical Surface Treatment of Stainless Steel by:

- Pickling (descaling) and Passivation

- Chemical passivation

- FOSFA Cleaning

- Corrosion Treatment

- Cleaning

- Degreasing

STAINLESS STEEL SURFACE BUFFING - GRINDING - POLISHING - WELDING

CLEANING OPERATIONS - PICKLING AND PASSIVATION