Tank Cleaning

Specialized Cleaning & Surface Repair Treatment Services of Stainless Steel Cargo Tanks , Stainless Steel Heating Coils, Stainless Steel Silos and Marine (EGCS)Scrubber Towers

- Worldwide more than 35 years of experiences with chemical surface treatment & mechanical surface repair of stainless steel and with stainless steel Condition & Corrosion (Damage) Inspections

- Specialized in (immediately) solving corrosion problems and repairing surface damage to stainless steel materials

- Troubleshooting 24/7: Surface Treatment and Repair Specialists are available 24 hours a day, 7 days a week!!!

- The highest quality: Our team is consistently striving for the highest quality in providing services, performing work, delivering products and managing projects

- Our goal is to quickly and adequately solve your problem in the shortest possible time by carrying out our work efficiently and effectively, with quality, safety and the environment being paramount.

- Professional cleaning of stainless steel and other metals by Chemical Technical Cleaning

ISTECH stands at the forefront of tank cleaning operations and stainless steel surface treatment technology, serving a wide range of sectors worldwide. Its expertise includes the repair of corrosion damage on stainless steel surfaces, removal of pitting corrosion, extensive inspection services, refurbishment of stainless steel cargo tanks, and provision of various surface treatments for stainless steel. Below is a concise summary of its specialized cleaning services:

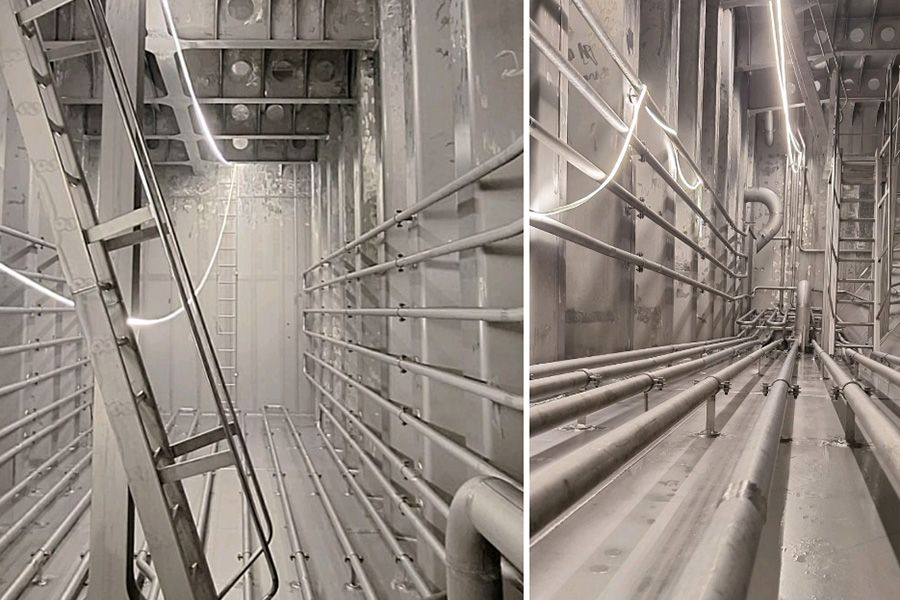

- Tank - Silo and Marine (EGCS) Scrubber Cleaning : Chemical & Mechanical Surface Cleaning Treatments of Stainless Steel - and Aluminium Tanks and Silos Worldwide including cargo tanks on board ships, tanks and silos (storage and processing) tank containers, rail-tanks, road tankers (new and used) Removal of crystallized products residues, removal of discolorations , removal of rust corrosion

- ISTECH Silvesta PAC - Powerful Acid Cleaning to remove (old) (Acid) product residues such as WET Phosphoric Acid green residues, deep dark (black) discolorations, (rust) corrosion spots by Chemical / Technical Cargo Tank Cleaning : Chemical Cleaning of Stainless Steel Cargo Tanks, Ready fFor Next Clean, Sensistive and / or Aggressive Chemical loads.

- Tank - Silo and Marine (EGCS) Scrubber Pickling and Passivation: Cleaning Operations & Surface Treatment by Pickling (Descaling) and Passivation (Acid Cleaning) conform to International Standard Practice ASTM-A380 of all sizes stainless steel tanks , silos and Marine Scrubbers worldwide.

- Stainless Steel Condition Inspections, Corrosion (Damage) Reports and tank cleaning advice.: Technical inspections or independent investigations for stainless steel tank surface condition, corrosion (damage) Reports and tank cleaning advice on board ships and for the whole worldwide industry (food grade and chemicals)

- Supply of Surface Cleaning & Treatment Chemicals: Mild Steel and Stainless Steel Cleaning Chemicals for cleaning, degreasing, chemical passivation, or pickling & passivation.

- Chemical Technical Cleaning (CTC): Chemical Cleaning or CTC of Mild Steel and Stainless Steel equipment and piping (such as tanks , scrubbers, steam pipes, cargo lines, etc).

Before Tank Cleaning

After Tankcleaning

Our technical services (on site works):

- Sanding, grinding, polishing of stainless steel

- Cleaning and polishing aluminum silos

- Cleaning stainless steel tanks mechanically and chemically

- Pickling and passivating stainless steel tanks

- Polishing stainless steel tanks

- Chemical cleaning of marine exhaust gas cleaning systems ( marine scrubbers)

- Remove corrosion from stainless steel tanks

- Marine scrubbers corrosion damages solutions

- Pickling and passivation of marine scrubbers

STAINLESS STEEL SURFACE BUFFING - GRINDING - POLISHING - WELDING

CLEANING OPERATIONS - PICKLING AND PASSIVATION