Stainless Steel Cargo Tank Pickling and Passivation

Stainless Steel Surface Treatment and Surface Repair

Pickling and Passivation of Stainless Steel Tanks and Silos

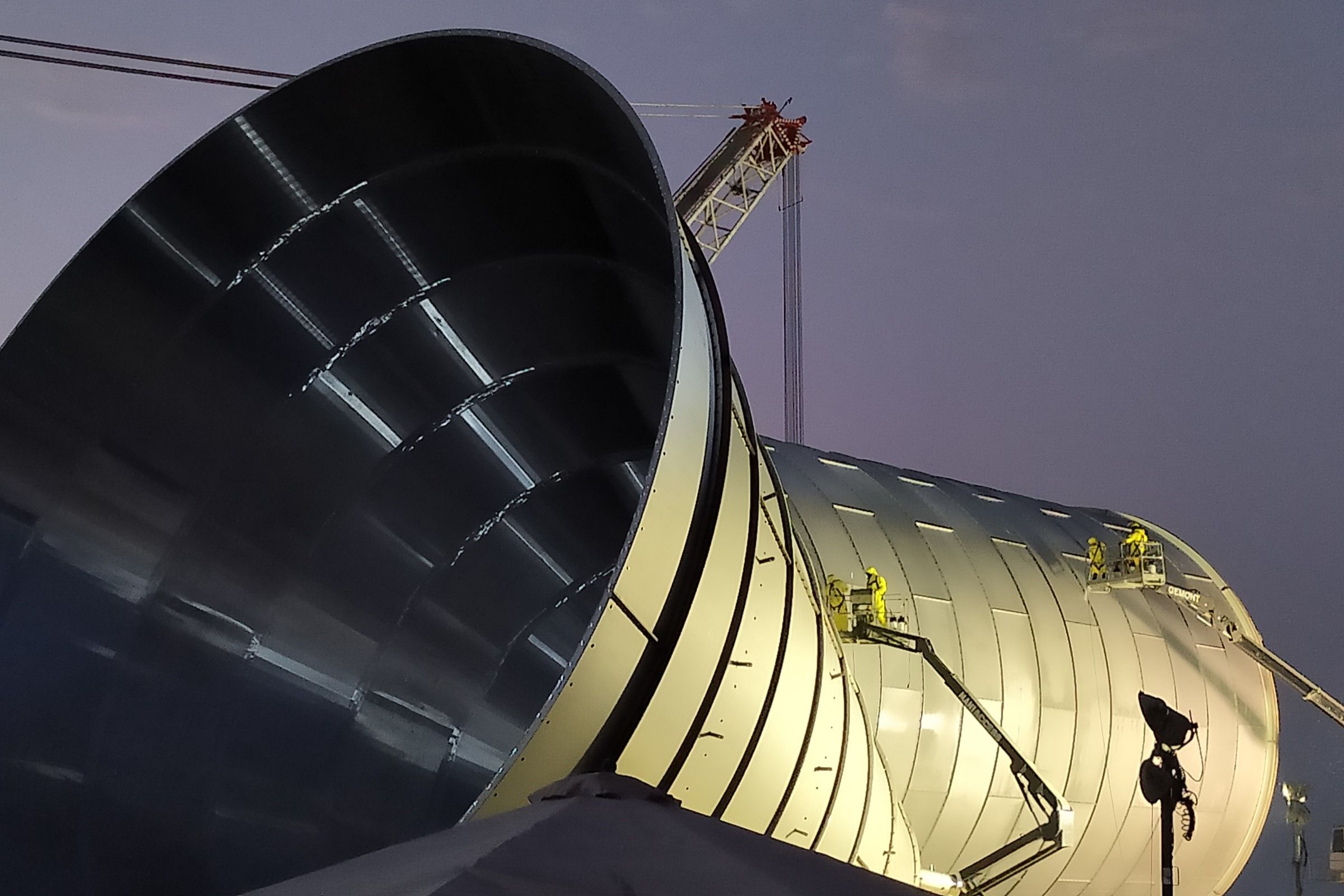

An expert team is present on-site to deliver surface treatment and repair services, crucial for the proper chemical and mechanical enhancement treatments leading to the final state of stainless steel cargo tanks.

Expert solutions for corrosion damage to stainless steel caused by aggressive acid cargoes, such as sulfuric and phosphoric acids.

Oceanwide Stainless Steel Cargo Tanks, Marine (EGCS) Scrubbers, Piping Systems (heating Coils) Services

Stainless Steel Condition Inspections, Stainless Steel Surface Treatment & Repair and Cleaning Services

ISTECH has over 35 years worldwide experience in Stainless Steel Condition Inspections, Stainless Steel Cleaning Operations & Surface Treatment for the:

- Maritime Shipping

- Inland Shipping

- Offshore Industry

- Petrochemical Industry

- Manufacturing Industry

- Food & Beverage Industry

- Fishing Industry

- Pharmaceutical Industry

- Local Government

Services

ISTECH Metal Finish BV offers a comprehensive suite of cleaning operations and surface treatments, drawing on a deep knowledge and understanding of stainless steel conditions related to corrosion damage, (ferrous) contamination, cleanliness, smooth finishes, and passivation.

Condition & Damage Inspection

Grinding &

Polishing

Pickling & Passivation

ISTECH Metal Finish B.V. - What makes us so unique

- Extensive knowledge of Stainless Steel and Corrosion

- Over 35 years experience in Stainless Steel Chemical Surface Treatment and Mechanical Surface Repair Worldwide

- Experts in Worldwide Cleaning and Troubleshooting

- Turn-Key Projects

- Quick respond to resolve customer queries as quickly as possible

- We believe in delivering the highest quality of work to our projects and successful completion of each project

- Our Experts and Specialists are 24/7 stand-by and ready to go anytime and anywhere in the world

- Our goal is to fix your problem and to get your vessel or equipment up to normal standard operating or running conditions with minimal down time

ISTECH - What makes us so unique

- Extensive knowledge of Stainless Steel and Corrosion

- Over 35 years experience in Stainless Steel Chemical Surface Treatment and Mechanical Surface Repair Worldwide

- Experts in Worldwide Cleaning and Troubleshooting

- Turn-Key Projects

- Quick respond to resolve customer queries as quickly as possible

- We believe in delivering the highest quality of work to our projects and successful completion of each project

- Our Experts and Specialists are 24/7 stand-by and ready to go anytime and anywhere in the world

- Our goal is to fix your problem and to get your vessel or equipment up to normal standard operating or running conditions with minimal down time